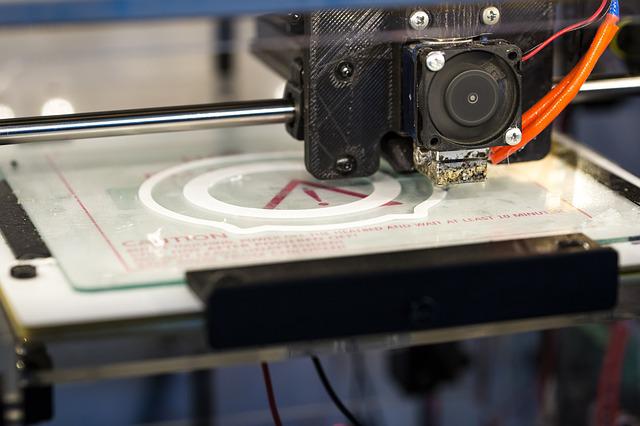

Topology optimization empowers planners to accomplish a cautious harmony among strength and moderateness, deciding how to make a section that is areas of strength for adequately the most un-material conceivable. It does as such in a manner that would be unbelievably challenging to accomplish without the assistance of a PC. This can here and there bring about a few odd shapes, which is the reason Topology optimization remains inseparable with added substance producing; 3D printing is the best instrument for assembling these complicated parts.

Topology optimization programming at last empowers planners to exploit the opportunity presented by added substance fabricating. Notwithstanding, as of not long ago, it was restrictively costly for the vast majority item groups. It’s just in the beyond couple of years that geography advancement has turned into an underlying component in numerous famous CAD programs, making it undeniably more available. This is the very thing item groups need to be familiar with this amazing asset.

How topology optimization functions?

The most famous and pragmatic topology optimization techniques are limited component (FE)- based. FE alludes to a plan technique that depends on reenactments to figure out which region of an item aren’t fundamentally basic and can along these lines be possibly eliminated.

The initial step to FE-based topology optimization is characterizing the heaps, installations, limitations, and “plan space,” or the most extreme volume that a given part might possibly involve. The product will then break down the particular restrictions to offer a few section plan choices and guide the creator toward the most ideal plan. At the point when a plan is chosen, the product will rehash the cycle to refine the calculation

By and large, parts planned utilizing topology optimization utilize less material to accomplish something similar or improved results, meaning direct expense reserve funds and a superior item. Since topology optimization can cut abundance weight from many plans, the innovation is particularly famous for metal parts in the aviation and car businesses, the two of which benefit from expanded eco-friendliness when the volume or weight of part materials are diminished. Furthermore, on the grounds that topology optimization and added substance producing empower creators to intently impersonate natural shapes, the innovation is by and large progressively utilized for clinical applications.

Advantages of topology optimization

The upsides of topology optimization reach out past material decrease. A portion of its different advantages include:

An abbreviated plan process: Topology enhancement can radically decrease item advancement timetables — which means diminished costs. The computerized cycle by and large prompts better-performing parts in considerably less time than would be required for customary plan strategies.

Better execution: The best plan for a given part isn’t generally instinctive, and it’s conceivable that a plan group couldn’t ever have concocted it without the assistance of a PC. topology optimization calculations don’t have the inclinations that people do, so they will quite often ignore style and normal plan decides for further developed execution.

More prominent energy-and cost-proficiency: Topology optimization dispenses with any pointless highlights or material, lessening both waste and cost. In addition, on the grounds that these parts are lighter, they likewise will more often than not diminish energy interest in their end-use applications.

Famous topology optimization programming

Topology optimization programming can be bought as an independent instrument or a CAD-incorporated module. Two key part in geography advancement are Altair and Dassault Systèmes. Altair initially delivered the OptiStruct apparatus in 1994, and General Motors was its most memorable client. Dassault Systèmes is answerable for a few well known TopOp modules, including Tosca and ATOM.

A small bunch of well known CAD programs, including Solidworks and Creo, accompany worked in geography improvement devices. Note that these apparatuses will generally be less strong and highlight weighty than independent TO programming. All things considered, they are fit for giving significant bits of knowledge during the plan interaction.

Top Platform is another sort of CAD programming whose incorporated TopOp modules permit the information result of reproductions to straightforwardly drive plan boundaries, for example, factor divider thickness or cross section bar thickness, carrying new functionalities to the product scene.